»Ongoing changes in the legal landscape as well as variable requirements, depending on the import project, make an individual approach to obtaining proof of conformity necessary. Our local experts develop tailor-made solutions for the needs of your company.«

TATIANA KUZNETSOVA, HEAD OF DEPARTMENT CUSTOMS & CERTIFICATION, CONDOR KASAN

EAC – What you need to get your product certified for Eurasian distribution

For the import and distribution of goods in the Eurasian Customs Union, proof must be provided that the goods meet local requirements. This mark of conformity requires a broad range of sometimes lengthy test procedures.

A large number of products may only be imported to Russia and the rest of the EAEU (Eurasian Economic Union) if they comply with specific technical regulations and have passed certain conformity procedures. The purpose of such regulation is to ensure that dangerous, harmful, inferior or undesirable goods do not enter circulation. As such, the goods must be marked with a quality certificate similar to ones in the EU, such as TÜV or CE.

Foreign manufacturers and exporters to the EAEU have been confronted with the fact that, since the merger of Russia, Belarus, Kazakhstan, Armenia and Kyrgyzstan into the Eurasian Economic Union, standardization of individual, national regulations have also resulted in a continued change in certification requirements. Certification now requires conformity to a system of TRs, or technical regulations, where specifications for different groups of products are uniformly regulated. This certification system successively replaces previous national systems such as GOST-R, state registration or FSB notification.

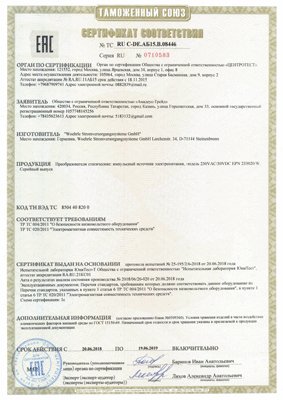

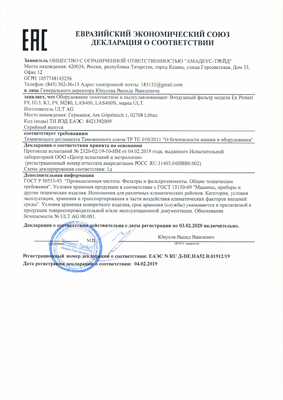

Proof of conformity can be provided in the form of a certificate of conformity by an accredited testing agency, or in the case that the risk potential of the goods is low, a declaration of conformity by a company established within the EAEU. So, for example, whereas a certificate must be requested for the import of a gas boiler, a declaration would be sufficient for the import of a pipe wrench.

Certification is possible for individual deliveries as well as for batches and serial productions, whereby a serial certificate generally entails stricter testing requirements.

Depending on the product and period of validity, testing for certification may include anything from document inspection to test reports from the factory and an independent laboratory as well as on-site inspection of the production facility.

The practical side effects of these requirements may not be obvious at first glance. But it’s worth considering that sample testing can be quite destructive, as lab testing usually tests a product beyond its stress limit – an undesirable result, for example, when it comes to the import of an expensive 3D printer prototype that might be destroyed in the process of certification. And how does the foreign sample even get to an ECU laboratory for testing if proof of conformity is required for import, you might ask? In this case, special customs procedures apply.

Ultimately, a tailor-made concept must be created for each separate product and every import project, taking into account individual requirements. We, at Condor, are happy to help you develop the detailed plan you need to facilitate a smooth certification process.

Deutsch

Deutsch  English

English  Français

Français  Русский

Русский